– Advertisement –

By Mohammed Jallow

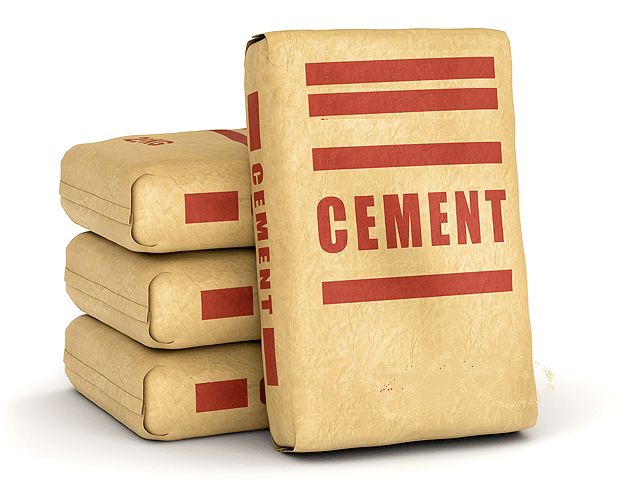

The cement industry in The Gambia today stands as one of the clearest mirrors of our broader economic contradictions. It is a sector that should symbolise industrial progress national self reliance and affordable shelter yet it has instead become a battlefield of profiteering import dependency and structural imbalance that punishes the poor while enriching a few. Cement in The Gambia has transformed from a basic construction input into a premium commodity traded with the psychology of scarcity and the pricing logic of luxury. This did not happen by accident. It is the product of policy inertia regulatory weakness import driven market capture and the failure to decisively protect and grow local production.

At the heart of this industry sits a simple but inconvenient truth. Only one company in The Gambia actually produces cement. That company is Salam Cement. All the others that dominate the shelves and flood the market are not manufacturers in the true sense. They are bagging companies. They import bulk clinker or finished cement grind or repackage it locally and sell it as Gambian cement while extracting margins that reflect international pricing rather than domestic cost realities. This distinction is not semantic. It is structural. It determines who bears the cost of foreign exchange who creates industrial jobs who invests in heavy capital equipment and who actually anchors value in the Gambian economy.

– Advertisement –

The major players that shape the Gambian cement market today include Salam Cement which operates the only full scale cement manufacturing plant in the country. Then there are Gacem Jah Oil Cement Gacem Gacem Trading and other brands that import and bag cement locally. These companies do provide employment and distribution but they do not carry the burden of industrial risk. They are traders with industrial branding. They benefit from global price swings when prices rise and rarely pass savings to consumers when international prices fall.

This reality explains why cement has become a premium product in The Gambia. When a country depends almost entirely on imports for a critical construction input the domestic price becomes hostage to foreign exchange volatility shipping costs geopolitical disruptions and international demand cycles. The Gambia imports nearly all its clinker cement rods steel bars roofing sheets tiles paints sanitary ware and even stones. Only sand is sourced locally and even white and black basalt are imported for higher grade construction. The result is a building sector that is fundamentally exposed to external shocks.

Historically cement in The Gambia was affordable. In the 1990s and early 2000s a bag of cement was a predictable cost that allowed ordinary civil servants traders farmers and migrants to build incremental homes over time. Construction was a pathway to dignity. A family could buy a few bags every month and slowly raise walls. That social contract has been broken. Today cement prices swing wildly and often remain artificially high even when supply is stable. A bag of cement now competes with food in household budgets. It is no longer a basic commodity. It has become a luxury input in a poor country.

– Advertisement –

The transformation of cement into a premium product is rooted in the liberalization of imports without a corresponding industrial policy. For years The Gambia opened its ports to cement imports without building protective frameworks for local production. Traders were allowed to import at will. Licenses were issued with little strategic consideration. Customs duties were adjusted to maximise revenue rather than industrial growth. The result was a market dominated by traders rather than producers.

Salam Cement entered this market as a true manufacturer. It invested in heavy machinery grinding mills storage silos power generation systems and skilled labor. It assumed risks that bagging companies never had to face. It committed to long term industrial presence. Yet instead of being protected and incentivized it was thrown into a gladiatorial arena with importers who could dump cheap cement when it suited them and raise prices when the market tightened.

The current situation reflects this contradiction. Cement prices are high not because local production is expensive but because the market is distorted by import dependency and speculative trading. When ships delay when foreign currency tightens when global demand spikes Gambian consumers pay the price. Traders pass every fluctuation to the market instantly. There is no price stabilisation mechanism. There is no buffer stock strategy. There is no disciplined import planning.

Government reaction to this crisis has been largely reactive rather than strategic. Periodic bans or restrictions on cement imports have been imposed only after public outcry. These measures often come too late and are lifted too soon. They are not embedded in a coherent industrial policy. A true government response would have prioritised the growth of Salam Cement and encouraged at least one or two additional full scale factories. It would have provided tax incentives power subsidies port rebates and foreign exchange support to manufacturers rather than traders.

Honorable Mod K Ceesay as the new Minister of Trade Industry and Employment inherits a sector that is crying out for reform. His task is not merely to manage prices but to reshape the structure of the market. The first gate advice he must embrace is that a nation that does not manufacture its cement is not building its sovereignty. Cement is not just a product. It is the foundation of housing schools hospitals roads ports and industrial parks. Whoever controls cement controls development.

The second advice is to differentiate between manufacturers and baggers in policy and regulation. They should not be treated the same. A factory that invests tens of millions of dollars in plant and equipment should not compete on equal footing with a trader who rents a warehouse and a bagging machine. Tariff structures must favor clinker import for local grinding rather than finished cement import. Power tariffs for manufacturers must be reduced. Port charges for raw materials must be rationalized. Access to foreign exchange for industrial inputs must be prioritised.

The third advice is to establish a cement price stabilization framework. Government through GGC or a designated body should maintain strategic cement reserves to smooth supply shocks. A transparent reference price based on production cost and reasonable margin should be published. Traders who exceed this range should be investigated. Price control should not be crude. It should be intelligent data driven and fair.

The traders themselves must also reflect. They have made enormous profits from the cement trade. Yet many of them have not reinvested in production. They remain importers in a country that desperately needs manufacturers. They should pool resources to establish additional factories rather than compete only in packaging and branding. The era of easy margins from import arbitrage must end if The Gambia is to build sustainably.

Public reaction to cement prices has been one of anger frustration and resignation. Young people who dream of owning a home now find that the first bag of cement is already out of reach. Diaspora remittances that once built neighborhoods are now swallowed by inflated construction costs. Land may be available but building it has become a financial nightmare. This is not just an economic issue. It is a social justice crisis.

The poorest Gambians are the most affected. They build incrementally. They buy five or ten bags at a time. Every price increase delays their dreams by months or years. A society that allows cement prices to spiral without restraint is telling its poor that shelter is not their right but a privilege.

The largest consumers of cement and building materials in The Gambia include the government which builds roads schools hospitals housing estates and public infrastructure. Real estate developers who construct apartments hotels and gated communities consume massive volumes. The tourism sector constantly expands resorts lodges and facilities. Religious institutions build mosques and churches. The diaspora builds family homes. NGOs construct clinics and community centers. All these actors drive demand yet it is the small household builder who bears the greatest burden of price volatility.

Looking to the future the Gambian cement industry stands at a crossroads. One path leads to deeper import dependence higher prices and greater vulnerability. The other leads to industrialization job creation price stability and national resilience. If Salam Cement is supported and if new factories are encouraged The Gambia can become a net producer rather than a captive importer. We have port access energy potential and regional markets. We can supply southern Senegal Guinea Bissau and beyond.

But this will not happen by rhetoric. It requires bold policy decisive regulation and a willingness to challenge entrenched trading interests. It requires a government that understands that cheap cement is not anti business but pro development.

The cement question is ultimately a question of what kind of country The Gambia wants to be. A nation that builds with imported hands and pays foreign prices or a nation that manufactures its own future. The choice belongs to policymakers traders and citizens alike. History will judge whether we chose convenience over sovereignty or industry over importation.